BERLIE BELT FILTER PRESS

Turnkey Projects Installations

Impressive advantages

Very low electrical cost compared to centrifuges

Relatively low equipment and installation costs

Produces dehydrated sludge ready for further processing or for land spreading

Operates with minimal supervision due to its high level of automation

Provides stable and reliable operation adaptable to frequent product variations

Requires minimal space

Reliable equipment – Useful and ecological end product

Dehydrates municipal and industrial sludge and produces cakes to be further processed as fertilizers, combustibles or inert aggregate material

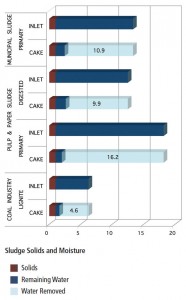

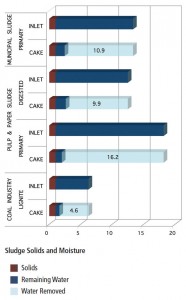

Processes sludge from inlet solids content as low as 1.5%, if installed with a draining table from Berlie Technologies Inc., and can dehydrate to dryness up to 15% to 45% depending on the composition of the sludge

Maintenance costs are very low and predictable

Superior results

Quebec City has 5 belt filter presses on site purchased from Berlie Technologies Inc. These presses currently dehydrate the municipal sludge from a population of approximately 600,000 people. This amount of primary wastewater treatment sludge, which is currently of 50 dry metric tons per day, corresponds to the capacity of 2 ½ of the 5 belt filter presses installed, each of which has a belt width of 2.5 meters.

This sludge is dehydrated from approximately 5% in solids content at the inlet to approximately 27% at the outlet.This amounts to a belt loading of about 745 pounds of dry solids per meter of belt width per hour. The dehydrated sludge is then conveyed to the rotary dryers and, finally, to the incinerator as an additional fuel source of which the calorific value is estimated to be of 13.4 MJ/Kg.

BERLIE BELT FILTER PRESS

with belt widths from 1 to 3 meters

Worldwide references

Berlie Technologies Inc. contracted and delivered, in turnkey projects, a large quantity of belt presses to municipalities, paper mills and other industries in North America and developed a wide expertise working with various sludges in combination with various polymers, belt types and press adjustments.

The system

Advanced technology

Solids loading can vary between 400 lbs (181 kg) to more than 1000 lbs (454 kg) per meter of belt width per hour depending on sludge properties.

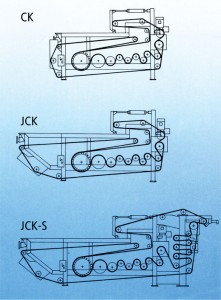

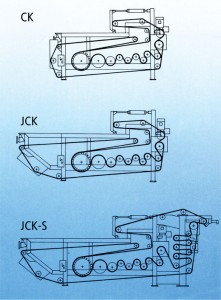

System configuration

Performance chart

Energy savings and recovery

Electrical consumption below 10 Kw-hr/dry ton processed.