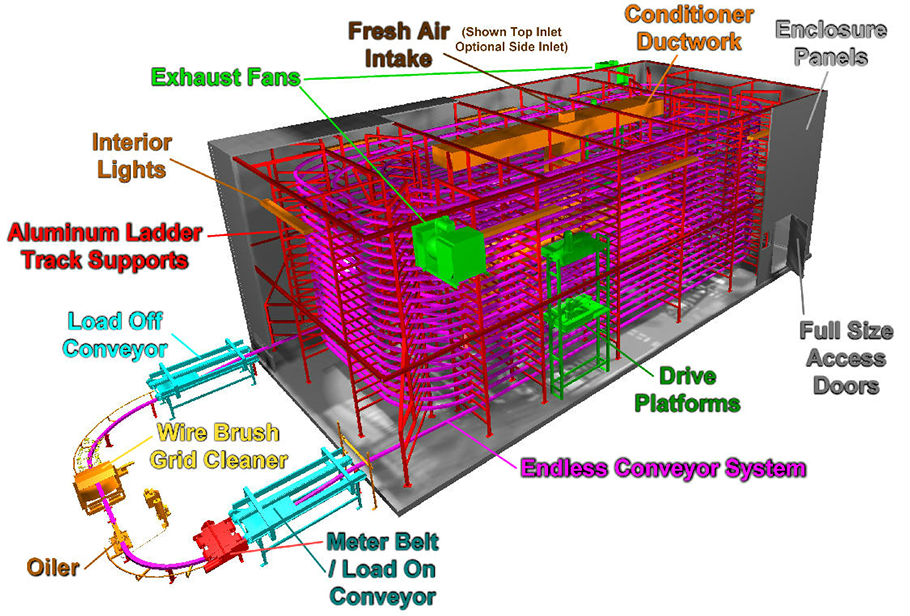

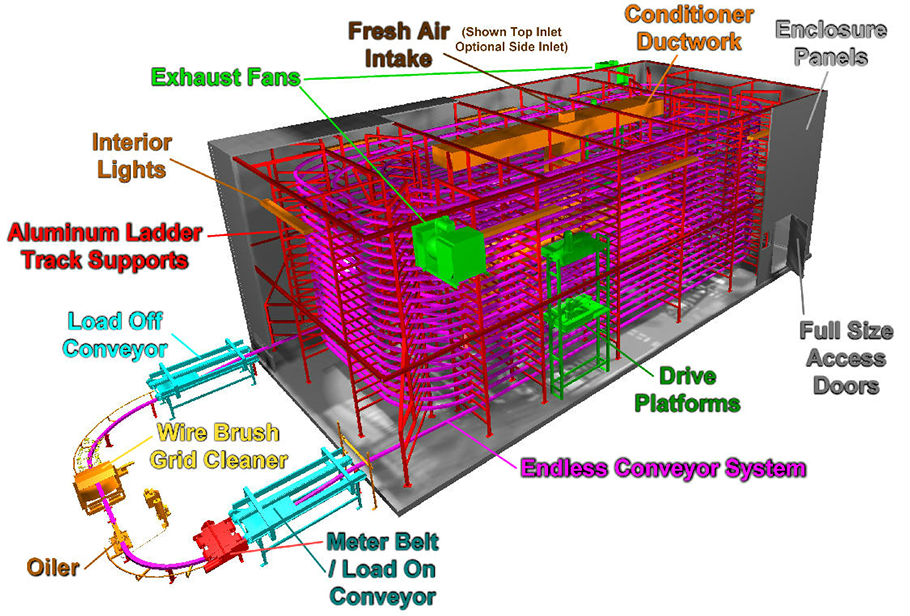

Automate the proofing process in your high volume production facility with a Stewart Systems Conveyorized Proofer (AKA - Continuous Proofer).

Proofed Cluster Buns - Stewart Systems Conveyorized Proofer, continuous proofing, high speed, industrial proofing & baking

The Stewart Systems Conveyorized Proofer provides a controlled environment that proofs your products easily and uniformly. Our proofer utilizes a downdraft conditioning unit and PID loop RTD/capacitive hygrometer controller to hold a stable relative humidity within very close limits (~1%). Programmable and easily adjustable variable speed drives control the time that your product is in the proofer allowing on the fly reconfiguration, if necessary.

Our patented magnetic pan grids facilitate the high volume pan handling that is necessary for your operation. They also allow the flexibility to accommodate a variety of pan sizes and shapes. The load on and metering conveyors are designed to work in tandem to force proper pan gaps. This allows you to properly space the product and manage proofer capacity.

Stewart Systems Conveyorized Proofer’s construction is rugged and reliable. The low maintenance design makes for long, low cost and reliable operation. The series 430 Stainless Steel enclosure and special camlock design eliminates corrosion problems. The chain and guide design is low-profile and stable, and eliminates the need for outriggers. This prevents the product contamination issues sometimes seen with other designs. Interior and exterior supports are made of heavy aluminum, and the track and grid are made of stainless steel.

The complete system includes diagnostic touch screen controls for simplified system monitoring. A quick exhaust and reheat capability preserves the product in the event of a process interruption. A fully networkable processor allows for advanced integration with other plant processes and equipment.