HIGH PRECISION MILK STANDARDIZATION

Tetra Alfast’s high precision virtually eliminates cream give-away, typically delivering a payback on investment within 1.5 yrs

Designed for multi-product processing and multiple component standardization, this unit offers great versatility

The SpotOn technology option means product changes can be made on the fly, saving time and reducing product waste

Tetra Alfast® S2

Direct In-line standardization

Tetra Alfast® S2 is designed for automatic in-line standardization of the fat content in milk and cream direct after milk separation, for standardised consumption milk.

Quickfacts

Unit for automatic in-line standardization of the fat, protein, total solids and solids-non-fat in milk and cream directly after a separator.

CAPACITY

5,000 to 75,000 l/h

APPLICATIONS

Market milk and cream, flavoured milk, milk for fermented products and powder production, cheese milk and other milk products

FEATURES

Multiple ingredients lines

Enables production of numerous dairy products

Additional ingredient lines can be connected to the standardizer, making this unit ideal for use in multi-product processing. A whole series of formulated dairy products are possible.

Multiple component standardization

Makes your line more versatile

Tetra Alfast has a unique ability to standardize not only fat content but also solids-non-fat, additives and protein, thanks to built-in software which regulates the mass balance. This feature is valuable when making cheese milk, for example, since the ratio of fat and protein entering the cheese vats has to be highly controlled in order to achieve consistent product quality.

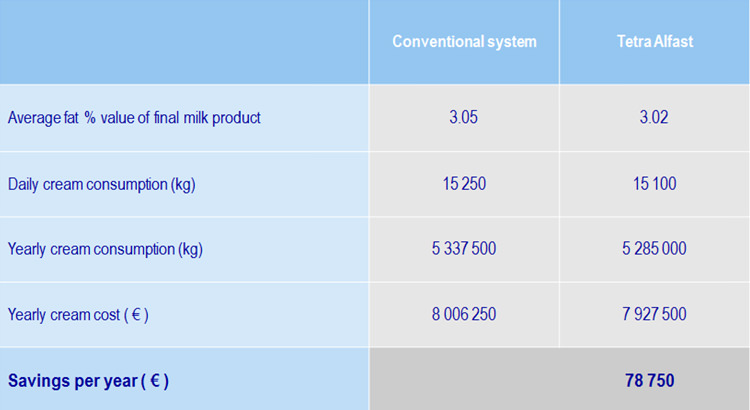

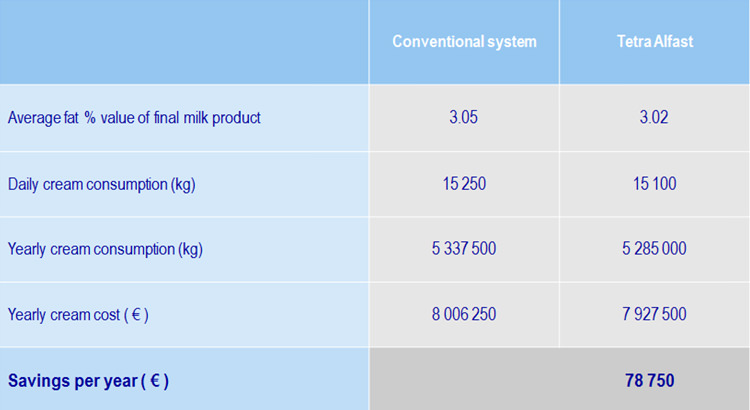

Advanced software

Minimizes cream give-away, maximizes profit

High performance measuring instruments send signals to a powerful computer, which rapidly makes calculations and instructs the regulation valve to fine-tune fat content. It enables an extremely precise result with negligible cream give-away, thus leading to significant savings. For example, over one year, achieving a fat content precision /- 0,02 % producers can save 78,750€ per year.

(This example is based on a cream content of 40%, cream cost of 1.5 €/kg, filling capacity of 10,000 litres per hr, 20 hrs per day, 350 days per year).