Flex-Turn®

Convey around corners while maintaining product orientation and spacing

Flex-Turn® conveyors gently move products around corners while maintaining proper product alignment and spacing. Flex-Turn® conveyors offer the tightest level transfer and smallest inside turning radius available. Compact in design, Flex-Turn® conveyors solve tight production line space problems.

Flex-Turn® Conveyor Advantages:

Gentle handling minimizes product damage

Maintains product orientation and spacing around turns

Unique non-collapsing tapered-pitch belt

Easy to use, clean, and maintain

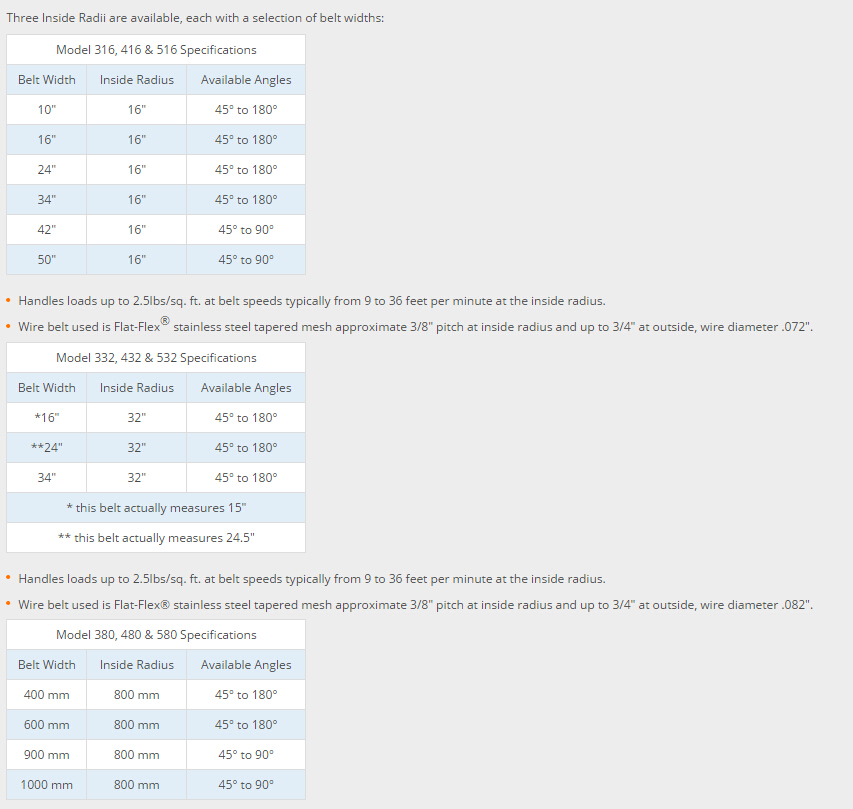

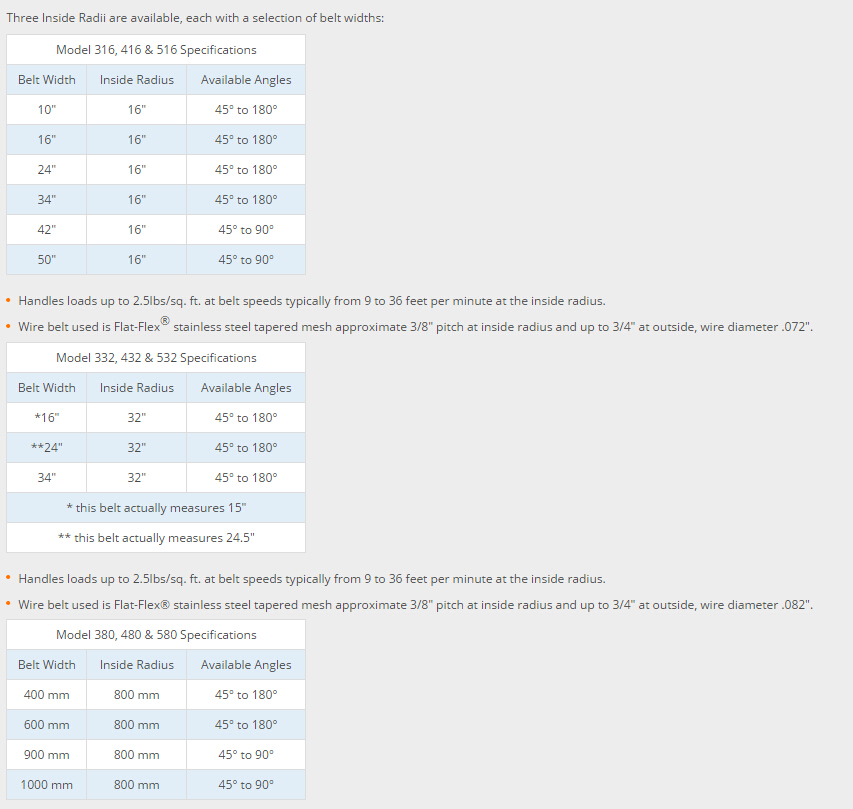

The Flex-Turn® range offers choices of size, belt width and configuration, providing a turn conveyor to suit almost every situation. Turns through 90° or 180° are standard, though other angles from 45° to 180° are available.

Three Series offer different constructions of the belt support:

The Series 300 Flex-Turn® conveyor is an open, stainless steel framed turn conveyor. This open structure allows for the easy removal of debris, and facilitates washing and draining.

The Series 400 Flex-Turn® conveyor has a solid polyethylene top. This prevents the product from falling through, or becoming entangled with, the strands of the belt.

The Series 500 Flex-Turn® conveyor has a solid stainless steel top, with stainless steel running rails. This option is particularly suited in some meat processing situations.

Specification

With a total of thirteen different sizes of belt, and a range of angles between 45° to 180°, there is a Flex-Turn® conveyor for almost every application. Our standard drive motors and controllers are supplied with IP66 enclosure protection and OS2 surface protection to ensure suitability for intensive wash down processes. If required, customer specified drive systems can be fitted to suit each individual application.

Designed to handle smaller products.

Handles loads up to 1.8 lbs./sq. ft. at belt speeds typically from 9 to 36 feet per minute at the inside radius.

Wire belt used is Flat-Flex® stainless steel tapered mesh approximate 1/4" pitch at inside radius and up to 13/32" at outside, wire diameter .062".

CarrySmart® conveyors can be customised and configured to suit customers’ individual requirements. Made to order designs can enable the customer to fit their own equipment on to, or inside, the conveyor. Conveyors can be supplied ready to install, or part finished for an OEM to complete.

Many options can be offered, including:

Trays under the conveyor

Guarding under, or over, the conveyor

PTFE running rails or transfer rollers, for higher temperature applications

Swivel lockable castors

Pivoting extensions

Alternative drive units

CarrySmart® manufacture custom conveyors for several OEMs, designed and developed specifically for them.