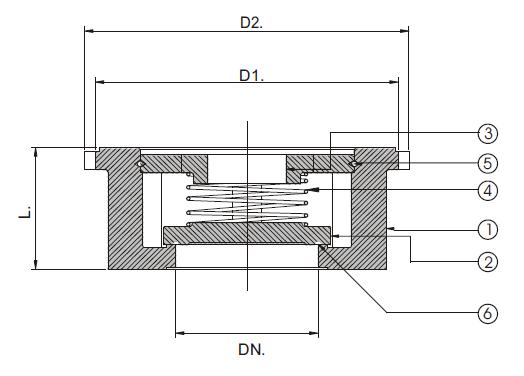

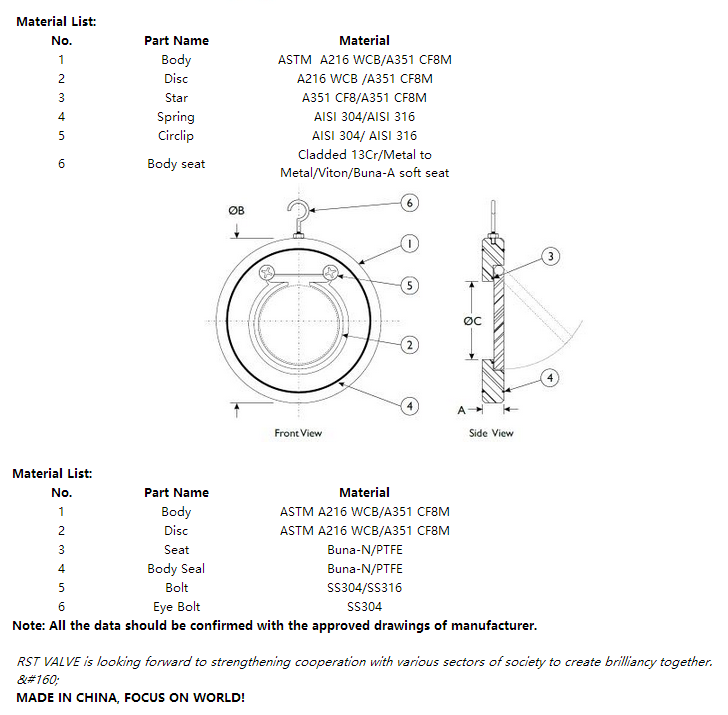

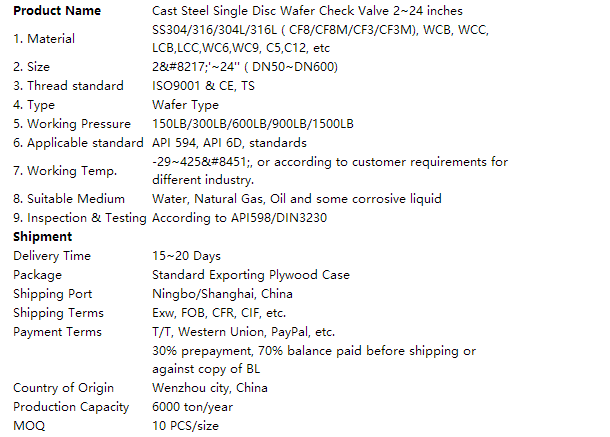

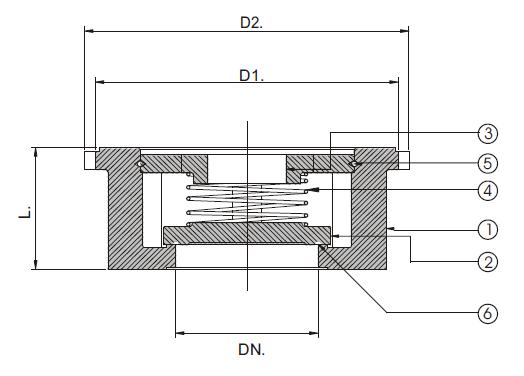

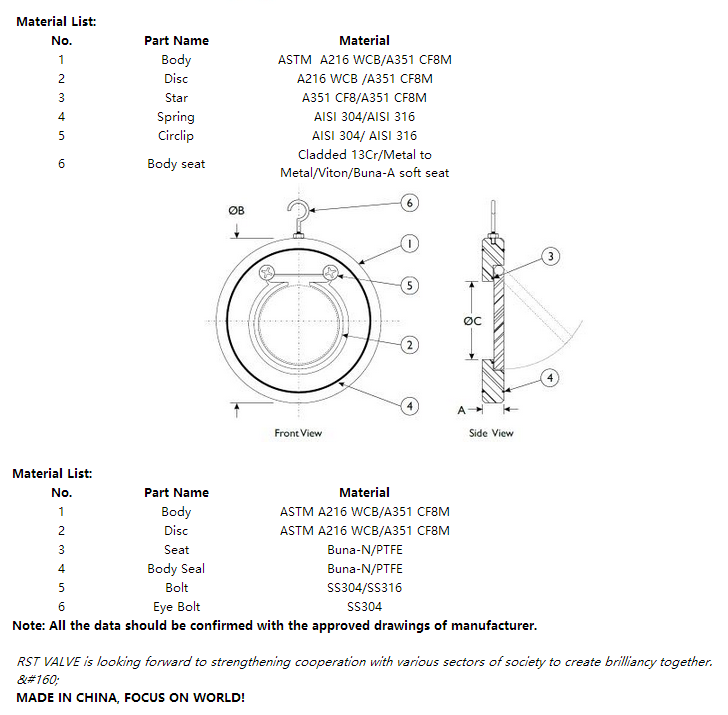

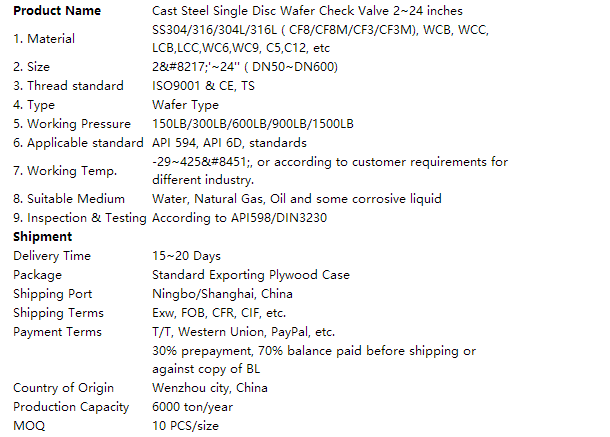

Cast Steel Single Plate Wafer Type Check Valve API/DIN standards

RST Valve company is a industry valves manufacturer, including Thread & Flange Ball Valves, Gate Valves, Globe Valves, Check Valves, Y Strainers in stainless steel, carbon steel, cast steel, forged steel and alloy steel.

Check Valves mainly has Thread ends Swing Check Valve, Stainless Steel Vertical type Check Valve, Screwed ends CF8M 200PSI Y type Check Valve, Stainless Steel Wafer type Check Valve, Single Disc Wafer type Check Valve, Single plate Lift type Wafer Check Valve, Dual Plate Wafer Type Check Valve, Cast Steel Flange ends Swing Check Valve, Stainless Steel Flange ends Lift type Check Valve, API Flange ends 150LB Swing Check Valve, DIN Standard Lift type Flange Check Valve.

Wafer Check Valves are available Solid Body, H-Body and Extended Body Designs in sizes up to 30". Body materials include Carbon Steel, 316 Stainless Steel, Cast Iron, Brass and Aluminum. Available elastomers include Buna N, EPDM, Viton, Silicon and Teflon. Valve internal components can be customized to fit your exact application requirements.

Full Port, Lowest Pressure Drop. Full Port Wafer Check Valves provide more flow and lower pressure drops than conventional check valves. Our elastomer hinge check valve design takes performance to an entirely new level by eliminating the restrictive valve seat and substantially increasing the valve’s open area and flow coefficient (Cv). They are ideal for application in vacuum pumps, compressed air and gas systems as well as in water systems where low head loss and elimination of water hammer are desirable.

Features:

1. Light weight,versatile design— 80% to 90% less than conventional full-body swing check valves

Simplifies piping

Reduces thermal and seismic considerations

Optimizes space utilization

Lowers installation costs

Reduces pipe supports

Requires less number of man-hours

2. Single Disc opening

Unobstructed flow

Stable disc at lower flow velocities

3. Single integrated arm/disc assembly Spring-loaded disc calculated to increase the responsiveness of the disc

No shearing of disc from arm

Non-rotating disc for longer life

No nut to back-off disc stem

4. Elastomer o-ring seat secured in body with dove-tail groove

Alleviates water hammer and resultant damaging effects

5. Integrated body seat

Field replaceable seat

Seat is out of the direct flow stream

6. Non-blow out shaft design

Improved safety to personnel and surrounding equipment

7. Outside mounted accessories externally supported

Increased control of valve performance

Long body seal life

Enhanced fugitive emissions control

Competitive Advantages:

Our products is guaranteed within 18 months after delivery.

We offer free sample if interest before orders.

Technology renovation, process improvement, structure optimization and quality improvement.

Excellent after-sales service system, providing timely and optimal service, which help you to win the market.

Convenient shipping sea port, and standard exporting carton boxes & plywood cases.

100% inspection & testing before delivery.

Third party inspection on customer requirement.